-

Disinfection is an effective measure to cut off the transmission of infectious diseases which is important in the prevention and control of infectious diseases. Temperature is one of the most important factors affecting the effectiveness of disinfection, and all commonly used disinfection techniques, whether chemical or physical, have a range of applicable temperatures. There are sometimes problems with disinfection in cold environments, especially as transmission of the severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2) from contaminated cold-chain shipments to humans has been listed as one of the possible transmission routes for the epidemic (1-2). Not only is it difficult to apply most physical disinfection methods at this time, but the commonly used chemical disinfectants freeze and are ineffective.

Therefore, in order to cope with the cold chain and the low temperature environment in alpine regions, there is an urgent need for research into low temperature disinfection technology. Some initial progress has been made in the field of cryogenic disinfection. In terms of chemical disinfection, several studies have shown that some disinfectants suitable for ambient temperatures can maintain their disinfection performance at low temperatures when certain conditions are met, such as the addition of antifreeze agents and increased doses of disinfectant, or thermal fogging with custom optimized thermal foggers (3-6). In terms of physical disinfection, research is directed towards ultraviolet (UV) light, γ-rays, X-rays, electron beams, microwaves, and high-voltage pulsed electric fields (7-10). But there are no clear and feasible disinfection methods or evaluation criteria yet.

This study used pulsed UV technology. The experiment was designed and the disinfection effect was determined in accordance with Technical Standard For Disinfection (2002 version) to investigate the disinfection effect of pulsed UV technology on two microbial indicator bacteria at different temperatures and on different carriers. The study was carried out to verify whether there was an effect of temperature on the disinfection effect of pulsed UV technology. The cloth sheet in the carriers is a conventional carrier for disinfection experiments. The stainless steel sheet was selected to take into account the possible need for disinfection in cold chain environments such as van walls and shelves. And the corrugated paper sheet was selected considering the outer packaging of common goods. Because the resistibility of coronavirus to ultraviolet light is weaker than that of bacterial propagules, a gram-positive bacterium Staphylococcus aureus and a gram-negative bacterium Escherichia coli were selected as indicator microorganisms.

-

The two bacterial species selected in this study were Staphylococcus aureus (ATCC 6538) and Escherichia coli (8099). Staphylococcus aureus (ATCC 6538) was from American Type Culture Collection (ATCC), Escherichia coli (8099) was from China General Microbiological Culture Collection Center (CGMCC).

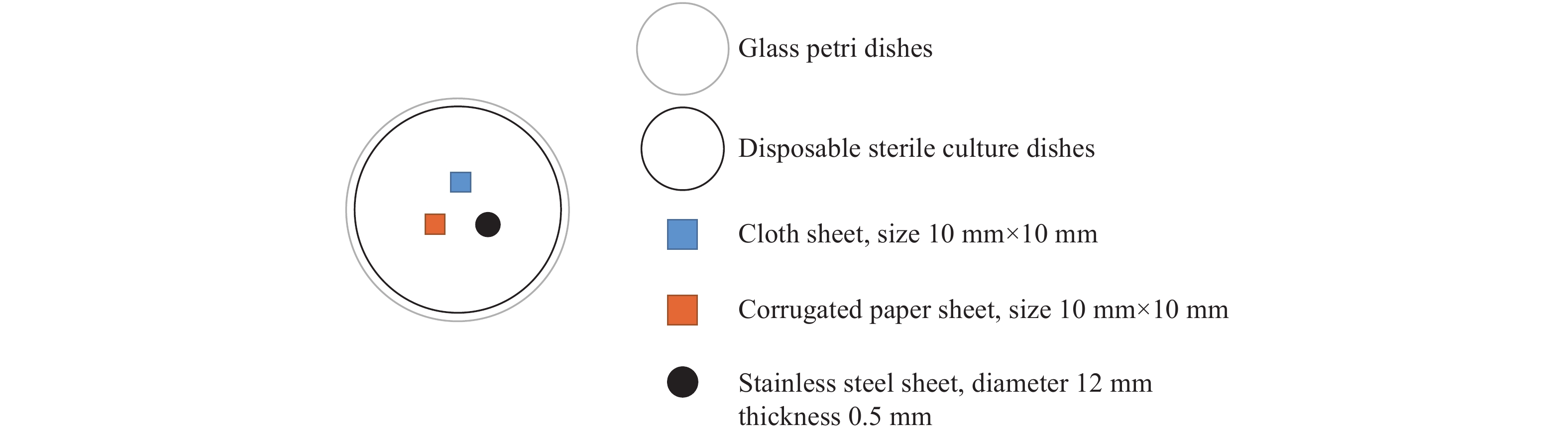

The three selected carriers were cloth sheet (10 mm × 10 mm in size), stainless steel sheet (12 mm in diameter and 0.5 mm in thickness) and corrugated paper sheet (10 mm × 10 mm in size). All carriers were sterilized by pressure steam before use. Among them, the production method of the corrugated paper sheet was to peel off the outer layer of the common corrugated cardboard box in daily life, and cut into square pieces of 10 mm × 10 mm. In this study, tryptone soy agar (TSA) was used as the medium, tryptone soy broth (TSB) was used as the organic interferent, and 0.03 mol/L phosphate-buffered saline (PBS) containing 0.1% tween 80 was used as a diluent.

The instruments required for this experiment include a heating and cooling circulator (the temperature is set to −20.0 °C, 0.0 °C, 20.0 °C, and the temperature difference is ±0.05 °C), a pulsed UV xenon lamp (model GZU7280, with a pulse flicker frequency of 20 Hz and an instantaneous irradiation intensity of 332.87 mW/cm2 at a distance of 1 meter), a hand-held infrared thermometer (the measurement range is −38 ℃ to 520 ℃, and the temperature difference is ±2 ℃). Other required equipment were 37 ℃ constant temperature incubator, electric mixer, graduated straws (1.0 mL, 5.0 mL), disposable sterile petri dishes, autoclaved spare glass petri dishes, and pipette (10 μL) and matching plastic pipette tips, etc.

Bacteria freshly cultured from 18 h to 24 h were diluted with TSB to the desired concentration. 10 μL of fresh bacterial propagule suspension was applied on the vector separately, and 16–19 pieces of each bacteria carrier were prepared, of which 12–15 pieces were used for the test, 2 pieces were used as positive control, and 2 pieces were set aside. The amount of recovered bacteria for positive control should be 1×106–5×106 CFU/tablet.

The stainless steel tablets were placed in a constant temperature incubator at 37 ℃ for 20 minutes to dry and ready for use. The corrugated paper tablets were set at room temperature (25 ℃) for 15 minutes to dry and reserve, and the cloth tablets for 5 minutes to dry and reserve.

The heating and cooling circulator was adjusted to −20.0 ℃ and the temperature was stabilized for the test. For each test, one piece of each of the three bacteria carrier was placed flat in a disposable sterile Petri dish with a glass Petri dish over it and put into the water bath of the heating and cooling circulator (Figure 1). The actual temperature of the carriers was measured and recorded with a hand-held infrared thermometer 5 minutes later. A pulsed UV lamp was placed above the water bath and fix the lamp height 10 centimeters away from the bacteria piece. The waiting time was set to 5 seconds, and the experiment was conducted in 4 groups respectively, with each group disinfecting for 15 seconds, 30 seconds, 1 minute, and 2 minutes. After disinfection, the bacteria piece was inoculated in an aseptic manner with appropriate dilution as the test group sample. The heating and cooling circulator was set to 0.0 ℃ and 20.0 ℃, and the experimental method to −20.0 ℃. Two pieces of each contaminated vector without disinfection by pulsed UV light were taken as positive control. The medium from the same test batch was used as the negative control.

Figure 1.

Figure 1.Schematic diagram of the placement of the contaminated vector in the water bath of the heating and cooling circulator during the test.

The test group samples, positive control and negative control were incubated in a constant temperature incubator at 37 °C for 48 hours to observe the results. The test was repeated three times. The results were observed and the killing log value were calculated. On the basis of this, Escherichia coli was tested again with three sets of disinfection times of 5, 10, and 20 seconds. This experiment is a quantitative carrier kill test, killing log value ≥3.00 can be judged as disinfection qualified, otherwise judged as disinfection failed.

Statistical Product Service Solutions (26.0, International Business Machines Corporation, Armonk, America) was applied to statistically analyse the data, comparing the differences in the disinfection effect of each influencing factor including temperature, irradiation time, carrier type, and test strain.

-

The test was repeated with a total sample size of 297. The disinfection effect of the pulsed UV technology on two microbial indicator bacteria on different carriers at different temperatures, expressed as the average killing log value (Tables 1–2). When the set temperature was 20.0 ℃, the average carrier temperature was 20.4 ℃, ranging from 20.1 ℃ to 20.7 ℃; when the set temperature was 0.0 ℃, the average carrier temperature was 1.3 ℃, ranging from −0.8 ℃ to 2.0 ℃; when the set temperature was −20.0 ℃, the average carrier temperature was −16.7 ℃, ranging from −18.7 ℃ to −15.0 ℃.

Test strain Bacterial vector Setting temperature (℃) Pulsed UV irradiation disinfection average elimination killing log value 15 s 30 s 1 min 2 min Staphylococcus aureus Paper sheets 20.0 1.42 2.81 6.40 >6.32 0.0 1.30 2.36 6.40 >6.32 −20.0 1.27 1.86 5.80 5.29 Stainless steel sheet 20.0 2.60 5.08 >6.32 >6.32 0.0 2.41 3.27 >6.32 >6.32 −20.0 1.51 3.38 >6.32 >6.32 Cloth sheet 20.0 >6.32 >6.32 >6.32 >6.32 0.0 >6.32 >6.32 >6.32 >6.32 −20.0 5.50 >6.32 >6.32 >6.32 Notes: Negative control sterile growth. Positive control number: 1.00×106–4.20×106 CFU/sheet. The mean logarithmic value of the positive control was 6.32. >6.32 indicates sterile growth in the test group.

Abbreviations: UV=ultraviolet; CFU=colony forming units.Table 1. Killing effect of pulsed UV light on Staphylococcus aureus under different temperature conditions.

Test strain Bacterial vector Setting temperature (℃) Pulsed UV irradiation disinfection average elimination killing log value 5 s 10 s 15 s 20 s 30 s 1 min 2 min Escherichia

coliPaper sheets 20.0 1.61 2.86 3.63 4.42 5.84 >6.31 >6.31 0.0 2.04 2.38 3.14 3.23 4.02 >6.31 >6.31 −20.0 1.82 2.01 2.45 3.37 3.77 >6.31 >6.31 Stainless steel sheet 20.0 2.65 4.41 4.37 >6.31 >6.31 >6.31 >6.31 0.0 1.98 3.60 3.62 >6.31 >6.31 >6.31 >6.31 −20.0 1.70 2.98 3.92 >6.31 4.35 >6.31 >6.31 Cloth sheet 20.0 2.75 4.28 >6.31 >6.31 >6.31 >6.31 >6.31 0.0 1.55 4.37 6.69 >6.31 >6.31 >6.31 >6.31 −20.0 1.37 4.88 6.21 >6.31 >6.31 >6.31 >6.31 Notes: Negative control sterile growth. Positive control number: 1.00×106–3.83×106 CFU/sheet. The mean logarithmic value of the positive control was 6.31. >6.31 indicates sterile growth in the test group.

Abbreviations: UV=ultraviolet; CFU=colony forming units.Table 2. Killing effect of pulsed UV light on Escherichia coli under different temperature conditions.

To enhance the comparability of the analysis, the same irradiation time as the Staphylococcus aureus was selected in the experimental results of Escherichia coli. That is, four sets of data with irradiation times of 15 seconds, 30 seconds, 1 minute, and 2 minutes. The four influencing factors of temperature, irradiation time, carrier type and test species were used as groups, respectively, and the mean killing log values were calculated for each group. The differences in the disinfection effect of each influencing factor were compared using a non-parametric test for independent samples. The value of P less than 0.05 indicates that the difference is statistically significant (Table 3).

The effect of temperature on the disinfection effect of pulsed UV light is limited. A non-parametric test of disinfection effectiveness for independent samples with temperature as a group at P>0.05, which was not significant, concluded that the difference in disinfection effectiveness at each temperature was not statistically significant. No significant effect of temperature on the disinfection effect of pulsed UV was found (Table 3).

The irradiation time is the influencing factor of pulse UV disinfection effect. A non-parametric test of disinfection effect for independent samples with irradiation time as a group found a significant P

-value, P<0.05. Further comparisons between groups, the P-values were less than 0.05 between all other groups except between the 1-minute and the 2-minute groups. This means that the differences in disinfection effectiveness between the groups were considered statistically significant within the irradiation time of 15 seconds to 1 minute. The longer the irradiation time, the better the disinfection effectiveness was. The carrier type is an influential factor in the effectiveness of pulsed UV disinfection. A non-parametric test of disinfection effectiveness was performed on independent samples using carriers as groups and found P<0.05. Further comparisons between groups, the P-values were less than 0.05 between any two groups, which means that the differences in disinfection effect of each carrier were considered statistically significant.

Influencing Factors Median (Q1, Q3) Statistics P Setting temperature 20.0 ℃

0.0 ℃

20.0 ℃6.31 (5.27, 6.32)

6.31 (3.72, 6.32)

6.26 (3.81, 6.31)1.792 0.408 Irradiation time 15 s

30 s

1 min

2 min3.63 (2.41, 6.21)

5.46 (3.38, 6.31)

6.31 (6.31, 6.32)

6.31 (6.31, 6.32)28.667 0.000 Bacterial vector Paper sheets

Stainless steel sheet

Cloth sheet5.55 (2.54, 6.31)

6.31 (3.70, 6.32)

6.32 (6.31, 6.32)23.292 0.000 Test strain Staphylococcus aureus

Escherichia coli6.32 (2.93, 6.32)

6.31 (4.74, 6.31)5.465 0.000 Abbreviation: UV=ultraviolet. Table 3. Comparison of the effect of different influencing factors on the effectiveness of pulsed UV disinfection.

The test strain is an influential factor in the effectiveness of pulsed UV disinfection. A non-parametric test of disinfection effect for independent samples with test strains as groups found P<0.05, which concluded that the difference in disinfection effectiveness between the two test strains was statistically significant.

-

There are a number of environmental and safety issues that may arise from the use of low temperature disinfectants. These include the safety risks associated with the high concentrations required for disinfection, the pollution of the environment caused by excessive use of disinfectants, the corrosion of metals and the potential for bacteria to acquire antimicrobial resistance, the short-term and long-term effects of disinfection by-products on human health, and the safety of storage and transport of disinfectants and raw materials. It is necessary to explore physical cryogenic disinfection techniques.

Conventional UV germicidal lamps are generally low-pressure mercury vapor discharge lamps, microwave induction lamps or UV light-emitting diode (UV-LED) (11-12), which is far less irradiating than pulsed UV. Ultraviolet germicidal lamp (GB/T 19258-2012) states that, for the nominal power of 36W double-ended lamps and single-ended lamps, measured at a distance of 1 m, the initial UV radiation illumination should be no less than 125.55 μW/cm2 and 139.5 μW/cm2 (13). And UV germicidal lamps are susceptible to environmental conditions and have poor applicability in complex environments. Continuous UV-LED is also susceptible to ambient temperatures and drive currents leading to higher solder temperatures, which ultimately affects disinfection efficiency (14).

Compared to this, pulsed UV technology has great advantages. Pulsed UV technology is a pulsed engineering technique using instantaneous discharge and special inert gas lamps to excite xenon gas in a pulsed form, emitting ultraviolet to near-infrared light. Its spectrum is very similar to that of sunlight, but thousands to tens of thousands of times more intense (15). It kills bacteria through the interplay of photochemical, photothermal and continuous pulse effects. Not only is the irradiation intensity high, the irradiation time short and no ozone or other harmful by-products have been detected, making it safer (16). Therefore, the pulsed UV technique was chosen for experimental exploration in this study. The GZU7280 UV xenon lamp used in this study has a pulsed flicker frequency of 20Hz. The instantaneous radiation illumination at an experimental distance of 10 cm was calculated by laboratory measurements and formula simulations to be approximately 11,845–13,000 mW/cm2.

This study intended to explore the initial application of pulsed UV technology in the field of low-temperature disinfection, and the influencing factors studied are mainly carrier temperature, test strains, carrier type and irradiation time. It was experimentally confirmed that the carrier temperature has a limited effect on the disinfection effect of pulsed UV. It was found that corrugated paper sheets were slightly less effective in disinfection than cloth and stainless steel sheets, suggesting that the type of carrier may have a greater effect on the disinfection effect at low temperatures. The disinfection effect of pulsed UV was also related to the irradiation time, the longer the irradiation time, the more desirable the disinfection effect. The disinfection effect of the Gram-negative bacterium Escherichia coli was found to be better than that of the Gram-positive bacterium Staphylococcus aureus overall.

This experiment verified that temperature has limited effects on the disinfection effect of pulsed UV, and irradiation time and carrier type are the influencing factors of pulsed UV disinfection effect. It suggests the feasibility of the application of pulsed UV technology in the field of low-temperature disinfection, and the preliminary application may be possible after an in-depth study.

However, there were some limitations in this study. In this experiment, only the contaminated carriers were controlled in low-temperature conditions, and the complete disinfection equipment was not put into the same environment. It was not clear whether there was an effect of ambient temperature on the irradiation intensity of the pulsed UV-Xenon lamp. Therefore, subsequent studies should be conducted in a simulated low-temperature environment to further verify the applicable temperature range of pulsed UV. The carrier type has a large effect on the disinfection effect of pulsed UV. Later tests should pay attention to the use of other common commodity outer packaging to make carriers, refine the experimental conditions, and verify the disinfection effect of pulsed UV.

-

Chengdu Gecko Medical Technology Co.

HTML

| Citation: |

Download:

Download: